Rust was once the bugaboo of every car owner in the land. Eventually, technology improved, and now it’s largely a solved problem for those in drier communities, at least. For modern Jeep Wrangler owners, though, corrosion in another form is rearing its ugly head. It’s all about aluminum.

The issue concerns bubbling and flaking paint and corrosion, most commonly seen on the door hinges and door panels of affected vehicles. The blight affects both the JT Jeep Gladiator and the JL Jeep Wrangler, and can seemingly affect any of these vehicles built from 2018 onwards. In turn, this common pain point has become a topic of much discussion on forums and beyond.

Corrosion is one problem, but for many owners, the response from Jeep has only compounded the issue. Scores of customers have reported their issues to dealers, and many have been left frustrated and unsatisfied in turn. So what’s going on?

Corrosion, But How?

The modern Wrangler (and Gladiator in turn) picked up a number of aluminum components in the latest generation. The aim was to cut weight and improve efficiency in turn. The JL model hit the market with an aluminum hood, tailgate, and doors, while the main chassis still relied on steel.

By eliminating the use of steel in these components, there’s no risk of rust, but that doesn’t mean there’s no risk of corrosion. Typically, it naturally forms a hardy aluminum oxide barrier on its surface. Unlike iron oxide, this layer is tough and remains bonded to the base material. However, under the right conditions, aluminum can still suffer deleterious corrosion. Still, if properly painted and prepared, an aluminum panel should hold up to regular environmental conditions with little to no corrosion for many years.

In the case of the Wrangler, though, corrosion is popping up in vehicles just a few years, or even months, after delivery. This corrosion is most typically seen as bubbling on the door hinges, or on the door panel in the surrounding area. Other common areas include the lower part of the door panel itself. In mild cases, small bubbles under the paint aren’t particularly noticeable, but the problem can easily progress to the point where large chunks of paint are flaking off entirely.

One of the prime ways that aluminum can corrode is when it comes into contact with a different type of metal. This is referred to as “galvanic corrosion” or “dissimilar metal corrosion.” This has led to a widespread belief in the Jeep community that the hinges themselves are the problem. Endless videos and forum posts claim that Jeep’s combination of steel hinges with aluminum doors is the root cause of the corrosion issue.

However, a reality check suggests that’s not entirely accurate. The simple fact is that the JL Wrangler’s door hinges are made of aluminum, not steel. Furthermore, if that were the source of the issue, Jeep’s engineers could have solved the issue years ago with a simple part substitution. Some have suggested that the steel door bolts are the cause, but it’s not a likely explanation. Particularly given many owners are seeing corrosion and bubbling occur in areas like the lower door panel, where there are no fasteners or steel parts at all.

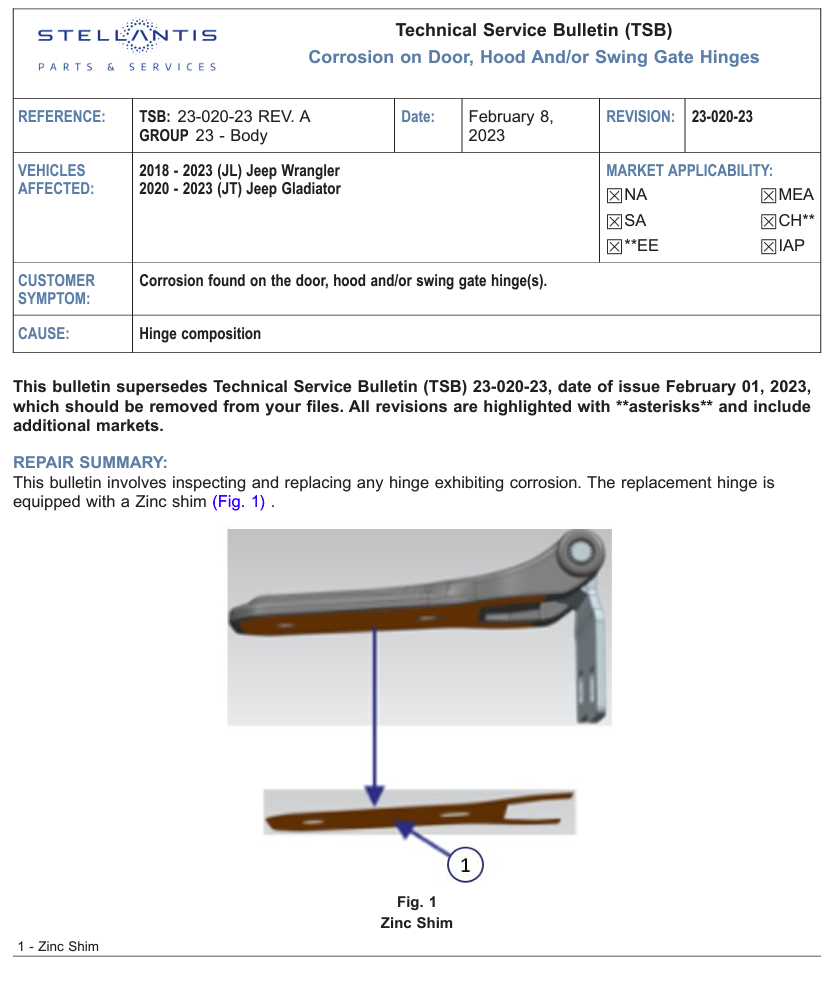

And yet, a move from Jeep to rectify the issue has added fuel to this common theory. In February this year, Stellantis issued a Technical Service Bulletin (TSB) regarding the matter. It instructs technicians to replace any corroded hinges with a new part that comes with a zinc shim. Zinc is often used as a “sacrificial anode” on submerged metal parts on ships. Thanks to Zinc’s greater potential for oxidation than metals like steel, it preferentially corrodes while leaving the structure intact. It hints at a galvanic corrosion issue at play here.

Jeep Blames The Aluminum Door And The Manufacturing Process

Here’s what a Stellantis spokesperson told us:

Model-year 2018 migration to an aluminum door design – a weight-saving measure – inadvertently coincided with, initially, occasional variation in the manufacturing process.

The issue described may occur in a fraction of these vehicles. Accordingly, we are providing affected customers with a solution.

It’s true that zinc will typically preferentially corrode over aluminum or steel. However, in this situation, having the shim corrode between the door and door hinge would be undesirable. It would lead to the hinge/door interface becoming loose over time, and there would still be unsightly corrosion byproducts, to boot. It could simply be a method to delay corrosion of the hinge/door area, rather than to stop it entirely.

Stellantis essentially confirmed this, saying: “The shim helps mitigate material properties that may induce corrosion.”

There are many related theories that are floating around various forums, some of which are more believable than others. Some suggest that Jeep’s paint process for its aluminum panels is not up to scratch. They suggest airborne contaminants, perhaps even tiny iron particles, are getting under the paint and causing the corrosion problems. That’s plausible, particularly given that it would fall under an “occasional variation in the manufacturing process” and this problem seems to have started for Jeep with the advent of the aluminum panels used in the JL and JT models. Indeed, Jeep’s own TSB for the repainting procedure states that “When sanding and prep is done you must use clean sanding pads and in a separate room from ferrous metals, as cross-contamination will lead to galvanic corrosion.”

Another theory suggests that the problem stems from the fact that Jeep paints the doors with the hinges already installed. Thus, there’s only a minimal primer coat, if that, between the hinge and the door. Thus, when water or other contaminants get into the hinge grooves, the corrosion problem begins. This could be plausible, though it doesn’t explain corrosion in other areas like the lower areas of the doors. It’s also likely that bolting together a fully-painted hinge and door would damage the paint anyway.

Repair And Despair

Naturally, customers are seeking repairs to their affected vehicles. Jeep offers a 5-year, unlimited-mile warranty for corrosion, so a great many owners have pursued a warranty repair on that basis. Repair involves either sanding down the affected panels and repainting them, or replacing them entirely.

Sadly, many have been frustrated by delays and poor repairs. Talk to owners on the JL Corrosion Information group, and they’ll tell you it’s been an unmitigated boondoggle.

Scott Anderson bought his 2019 Jeep Wrangler used in December 2023, picking it up in Tremonton, Utah. Having discovered corrosion on the vehicle, he headed to a local Jeep dealer to get the problem seen to. “They said I needed to go get a quote first from the body shop, as they did not have an in-house shop there,” says Scott. That would turn out to be a mistake.

“Because I got the quote first, it put me 2 days out of warranty,” Scott explains. He was told to contact the Jeep Cares customer assistance line, and he says he was told twice that the issue would be covered. “I had the appointment, and took it in on a Monday,” he says. “At 10 on that Monday they called and said they will not cover the repairs.” He’s followed up multiple times, to no avail. “Now when we call and give them the VIN, they hang-up,” he says. “First time Jeep owner, and last.”

Toddy Spencer is based down in Illinois, and he’s seen the same problems up close. “Mine is a 2018 so I caught right in time,” says Todd. “My corrosion is just on my hinges for now.” He knows he’s not alone, too. “I work for a dealership, and I see corrosion on almost all of them,” he says. As it stands, it’s looking like he’ll get his Jeep sorted by the factory, but there’s a wait involved. “I made a warranty claim back in February and I’m approved for all new door hinges, but parts are so backordered it will be another 6 weeks before they get to mine,” he says.

Complaints of delays abound, along with customers getting the runaround from Jeep Cares and dealerships. Average wait times seem to hover around 6 months to a year for those wanting a solution. Color match issues for repaired vehicles have also hounded some owners.

In fact, the more I kept digging, the more stories kept coming out of the woodwork. Ashley Dalton shared the photo above, showing a significant color-matching issue. “Many [body shops] do not blend into adjacent panels to achieve a decent paint match and hope the customer doesn’t notice,” Ashley told me. “Notice they didn’t blend into the adjacent panel so you can clearly see the mismatched paint at the edge of the door.”

Meanwhile, Paula Kay suffered warranty woes with her badly degrading white Wrangler. “My biggest issue with this is that I was told by Jeep Cares that they will not give me one cent due to being out of warranty, yet every day on here I see people out of warranty getting cost share assistance,” she says. After having an inspection appointment set up with a dealer, she says Jeep wasted her time by not even looking at the pictures taken by the service manager. “How do they pick and choose who they assist when out of warranty?” she asked.

As it stands, it appears a significant proportion of JL and JT models are affected. Used buyers would do well to carefully inspect any vehicles of this generation, and new buyers would be well advised to pay close attention to any warning signs on the paint.

It may be only a cosmetic issue, but it’s one that has seriously pissed off a great many Jeep owners. It’s not unreasonable for them to expect a five-year-old car to keep its paint intact. Much like the manual transmission issues Jeep has faced of late, it’s another case of Jeep failing at the very basics, and stumbling on repairs to boot.

(Image credits: Todd Spencer, Scott Anderson, Tristan Ray Geddes, Ashley Dalton, Paula Kay, Jeep)

Support our mission of championing car culture by becoming an Official Autopian Member.

-

Here’s Why You Might Not Want To Buy A Third-Generation Toyota Prius

-

The Popular BMW B58 Inline-Six Engine Has One Big Achilles Heel

-

Here’s Why Busted Plastic Grille Flaps On A Newer Car Can Cause A Check Engine Light

-

If You Want To Buy A Cheap Jaguar, Here’s An Engine You Should Probably Avoid

-

Honda Pilots Only Just Stopped Featuring This Ancient Engine Technology That Most Cars Abandoned Over 50 Years Ago

Got a hot tip? Send it to us here. Or check out the stories on our homepage.

Rust. It’s a Jeep Thing 🙁

Krysler Kwaliteeeeeeeeeeeeeeeeeeeee

Is there a Krown nearby? 😛

Rustproofing is a must! Hey, is that the new Mazda JX-9?

My rental Wrangler years ago had rust bubbling under the door sil paint and had 5,000klms on it lmaoo that was enough for me to remember why I don’t get the Jeep thing.

“Mr. Tracy, what is it going to take to get you into a new Jeep today?”

Stellantis should just blame all this on the Italian government.

Time to revisit plastic body panels.

Now I am pining for a Citroën Mehari.

They should rename the JT/JL the Aspen/Volare.

Stellantis: Bringing back the Chrysler quality of the 70’s!

Dealer: “We add value by advocating for the consumer with the OEMs”

Dealer: “No, we aren’t accepting your warranty claim work”

Déjà vu

Sounds like rust decided to invade the first Jeeps on the drawing board after David left. Was he secretly the hero that Jeep needed, keeping all rust at bay like some sort of reverse kryptonite?

And then rust swore vengeance on him, attacking all of his personal vehicles because it couldn’t get near Jeep?

DT is the human sacrificial anode. Wherever he is, he attracts all the corrosion.

This feels like a COTD to me!

“Bubble, Bubble, Toil and Trouble…”

Thanks for putting this back up!

Stainless steel to aluminum is a big no, better off using galvanized steel fasteners as they’re less reactive to aluminum. Probably need to add some sacrificial anodes. In the Hot Rod world I always see people wanting to run all stainless steel hardware, in their aluminum intake manifolds, heads, etc. with no understanding of dissimilar metals issue. Had a used aluminum intake manifold with a stainless steel bolt holding the coil mount, the bolt wouldn’t budge finally twisted it off and you could see the corrosion at the point next to the manifold.

Does locktite not prevent this?

Doesn’t prevent it at all, just slows it down a bit.

But I thought the whole point of Jeeps was to beat the crap out of them.

Oh wait, these are “jeeps” with doors.

What an asinine comment. Just because you may (or may not) be tough on a car whether off roading or not, doesn’t mean you would suddenly be ok with premature corrosion.

if you’re tough on it, it shouldn’t live long enough for corrosion to become an issue.

Bullshit.

Wrecking a $60k truck in less than 5 years would not be a point of pride for me.

I’m not saying it’s a good, smart, or financially viable thing; it’s just the original intended use case for jeeps.

Built by the lowest bidder for a bunch of hyperactive GIs to flog around in,

for a war that’s “going to be over in 6 months anyway”

This was always the inevitable end when they pivoted from selling a two door rig that was meant to be abused to a 40k plus rig with 4 doors to people that should frankly own a minivan.

On my 12 year old JK, I have a little bit of this where the hinges (aluminum) meet the steel doors, suggesting galvanic corrosion, at least in my case. However, it’s very small and not too noticeable. I was able to clean up the areas, file them down and use touch up paint to fix it. It’s easy to forgive some “warts” on an older vehicle like mine, but I’d be pretty upset if it were several years old or newer.

The problem with Jeep moving upmarket is that along with the higher price tag, the customer expectations will rise in step. Jeep wasn’t ever mean to be this fancy in my opinion, and they should just stick to the basics. It’s easier to forgive rough fit and finish when the tradeoff is a lower price tag, ease of maintenance and repair, and ability to modify.

You really think Jeep would do that? Charge $60k+ for something with the quality of a Ford Granada built on the Friday before a 3 day weekend?

Or $80k badge engineered 1970 era Lada Nivas.

Well I doubt they’re using aluminum bolts on the hinge brackets, so that could also be a cause?

Others have mentioned Fords having similar problem in the 2000s, and our 2005 Freestyle was one of them. It started bubbling up on the leading edge of the hood at about four year mark. The car was sold with a 10 year/unlimited mile rust/corrosion warranty but the word “perforation” is in the fine print…basically, unless there’s a hole, it’s considered superficial. I found that out when I took it back to the dealership. Our service writer took the additional step of popping the hood and looking at the backside with what appeared to be a pointed dental pick. In a few seconds, he said “perforation…there’s a hole here” and just like that, we got on the schedule for a new hood. I’m still not sure that he didn’t poke it through himself for the goodwill factor, but I’m not arguing. Still remember that guy fondly.

If he managed to poke through without much effort, it was completely rusted through. If there’s only a little bit of solid metal left, you’ll need a significant effort to poke through.

I think they meant that the paint bubble had to pop and make a hole in the paint, not that it had to rust all the way through the metal.

I don’t think so, he stated that Ford made the distinction between ‘perforated’ and ‘superficial’. I think a paint bubble would be considered superficial, even if there was a hole in that bubble.

Add this to the long list of reasons why I won’t own a Stellantis/Chrysler Jeep product.

Ford / Lincoln have the same issues on the lift gate. I have 2006 Navigator and my brother a 2005 Expedition and we both experienced bubbling paint on the lift gate. Many a Ford forum have a mountain of posts on the subject.

Funny my 1960 190sl has doors / hood/trunk all made of aluminum and I have never had any such corrosion rear it’s ugly head.

And hood. My folks had a 2009 (maybe?) Expedition EL and the hood (and tailgate) started doing this before the lease was up. Luckily it was rear ended so the new tailgate fixed the back side; the front though…

Owned 3 Chrysler products over the years: ’89 XJ Cherokee, ’99 WJ Grand Cherokee and ’00 300M (mistake). All bought used, all three had or developed serious corrosion issues.

You just can’t get rid of that AMC DNA.

Ha – all of them did have some AMC DNA, I forgot the LH cars evolved from the original fwd Eagle sedans and those were developed under the AMC/Renault era.

I wonder how many bros own a Wrangler who also dunked on Ford for making the F-150 aluminum bodied

I don’t see this on the Fords (but I’m not looking either). Have seen corroded Jeep door hinges for years.

I was just commenting on the fact that many people attempted to effeminize the F-150 for using aluminum, but I wonder how many inadvertently own an aluminum bodied truck thing (or just straight up don’t care anymore)

Why can’t Jeep/Stellantis get this right? Ever? I wanted a TJ for a while, but every damn one of them has rotted to the point I am scared to look under them. Even the ones that never went off road. And now this, which is especially galling given the prices.

Is it possibly an issue with painting the natural aluminum-oxide coating?

The rubber duckies on the dash will fix the rust right up.

Interesting unrelated van trivia of the day: One of the mistakes people make when replacing rusty body fasteners is going “Ah, stainless steel! The screw head will never melt off!” and using stainless steel screws everywhere. The problem is, as some reading on electrochemistry will exposit, that common 300 series stainless steels will cause every other metal around it to preferentially corrode. Steel, aluminum, zinc coated or not. The stainless steel will “win”.

This has been the cause of quite a lot of consternation with the vantrucks because it was hip for brushed-finish stainless steel accessories to be in contact with diamondplate aluminum. The result is the aluminum simply dissolved around the stainless steel carriage bolts, or the zinc pot metal limo trim turned to dust around its stainless steel bolts taking a fair chunk of the body sheet metal underneath with it.

When I did the resto work on one of mine, I did use stainless steel screws for attachment into the body – but they were 410 martensitic stainless steel, which is a lot closer in on the Galvanic series than common 304 screws. On aluminum (like the diamond tread running boards) I used Armorcoat screws (zinc-aluminum).

I hear stainless steel touching aluminum is also a big no-no in the boat world and it comes up often because owners don’t know better.

The best part of it all was that said running boards (aluminum) were bolted directly to the steel frame supports using stainless steel carriage bolts but regular galvie nuts.

Literally the most fetid soup of corroding metals one can imagine. I basically cut everything off and started over.

This surprises me. I’ve built a few things out of 6061 aluminum using stainless nuts, bolts, screws, and rivets without any signs of corrosion whatsoever. All these things are exposed to the elements for ten years now and show no signs of degradation. I am reasonably sure all the SS was 400 series, but I have no idea if that’s why I’ve had zero problems.

I’m probably a fool (I most definitely am), but I think of it as one of my go to building methods. Perhaps it’s time to do some research.

Exposure to the weather is fresh water.

Side steps and frame brackets get salt sprayed… whether by the DOT or by the beach.

Galvanic corrosion doesn’t always pop up at the point of contact between the dissimilar metals. It pops up at whatever location decides to “give up” it’s electron. That’s why you’ll see them apart from the hinge, around the hood, etc.

I own a ’23 gladiator and at least the ’23s have a shim/plate/spacer/thing already installed.